X-ray images examples for consumer goods

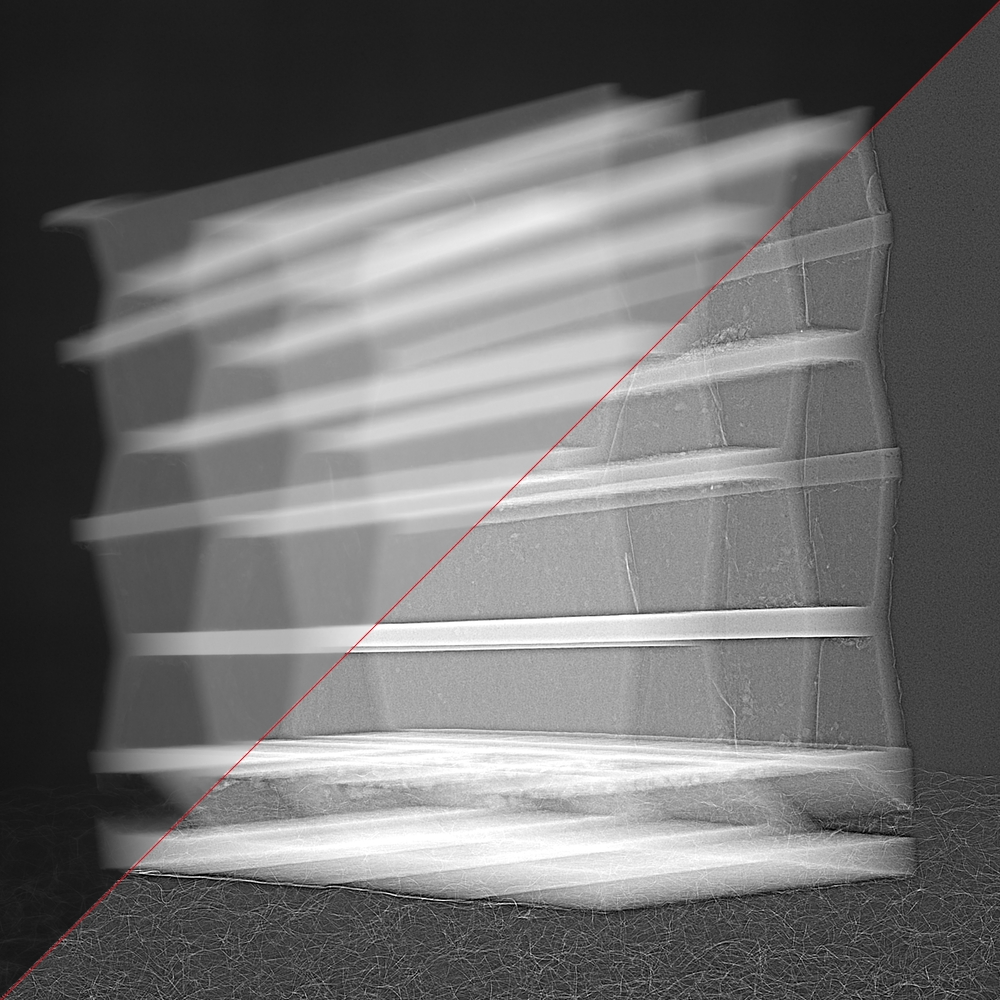

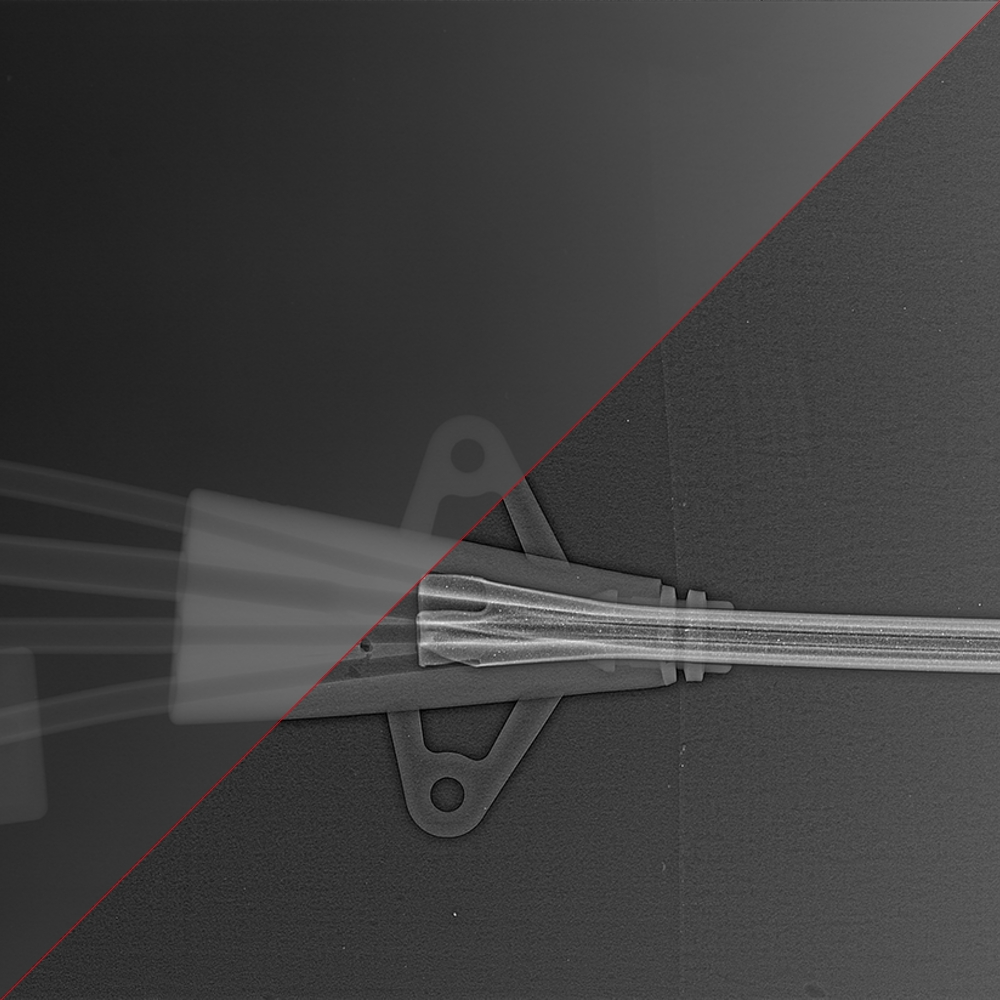

Composites

Mostly developed for the aerospace industry, composite materials are now extensively used in consumer goods. Depending on the application risks and their consequences on the consumer health/well-being, the system performances (image quality, speed) must be balanced with its cost. For example, a motorcycle helmet will require a more severe inspection than a tennis racket.

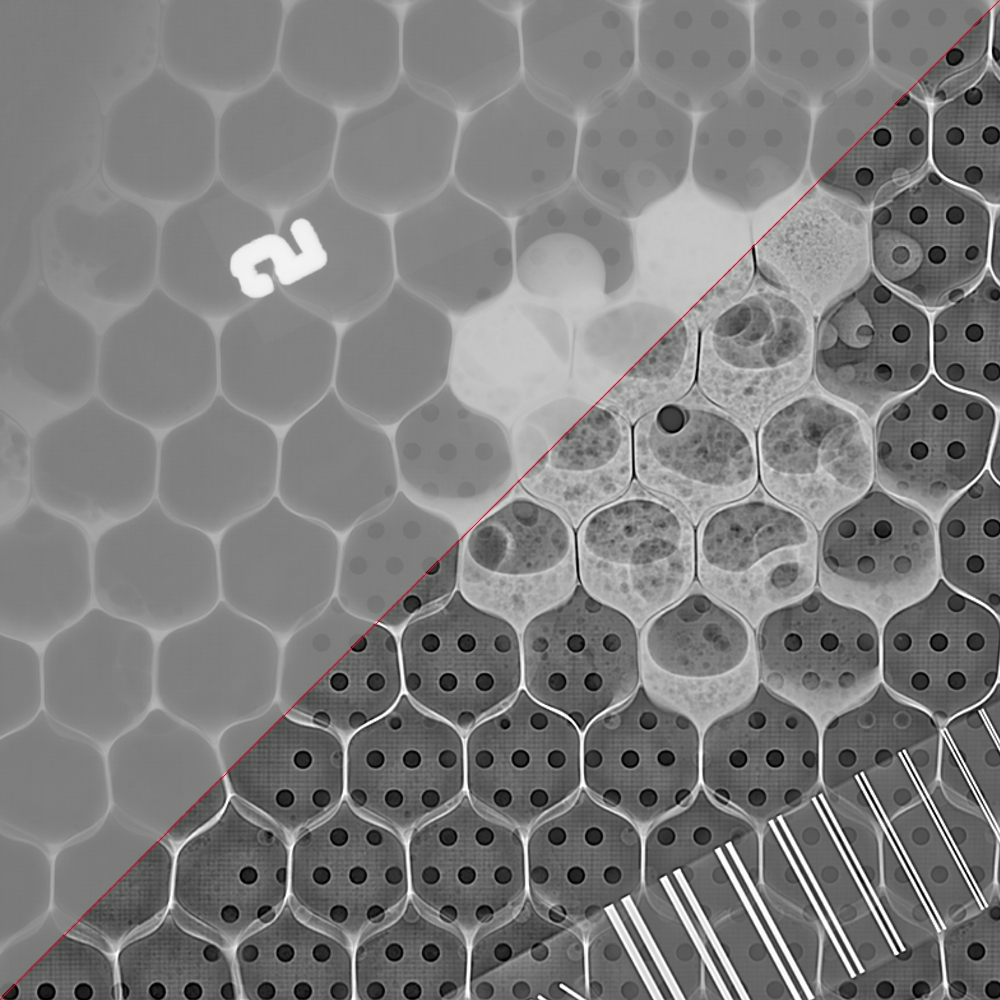

Electronics

Electronics plays an increasing role in our lives nowadays.

The radiographic inspection of electronic components faces three main challenges. Firstly, the miniaturization calls for a high resolution system to enable defect detection (open solder joints, cracks,…). Secondly, the components are highly sensitive to x-rays; the system must then carefully be particularized to the application. Finally, the system must be able to cope with the large volume of production by scanning multiple parts in a short amount of time.

Typical components include high voltage switches, insulators, solder joints, batteries, printed circuit boards, surface mount technologies, breakers, fuses, …

Food

When it comes to food inspection, detection of foreign bodies is of paramount importance. These bodies can either be external and accidentally introduced during the manufacturing process (glass, metal, …) or should have been removed in the process (bones in fish or chicken,…). Additionally, packaging seals can also be inspected with x-rays.

Accurate and efficient solutions with high-speed detection capabilities are required to be installed in in-line production to reduce the inspection costs of the company.